Learn how piping materials and allowable stress are selected in ASME B31.1 power piping. Understand carbon steel, alloy steel, stainless steel, temperature effects, creep behavior, and common material selection mistakes with real plant examples.

Table of Contents

Introduction: Why Material Selection Is Different in Power Piping

In piping engineering, many beginners assume that material selection is the same everywhere—pressure comes in, pipe size comes out, and a material is chosen from a table. This assumption may work for some low-temperature systems, but it fails badly in power piping.

ASME B31.1 power piping systems operate under high temperature for long durations, often decades. Under these conditions, materials do not behave the same way they do at room temperature. Strength decreases, deformation accumulates slowly, and failure mechanisms such as creep become dominant.

This is why material selection in ASME B31.1 is fundamentally different from material selection in oil and gas process piping governed by ASME B31.3.

This article explains:

- Why materials matter more in power piping

- Which materials are commonly used

- What allowable stress really means

- How temperature and time affect material strength

- Typical material selection mistakes seen on real projects

The discussion assumes the reader already understands ASME B31.1 scope, line identification, and design conditions, as covered in the foundation article.

Why Material Selection Is Critical in ASME B31.1

In power piping, materials are not selected only to withstand pressure. They must also:

- Retain strength at high temperature

- Resist long-term creep deformation

- Survive repeated thermal cycles

- Remain weldable and inspectable over plant life

A material that looks strong on paper at room temperature may become unsafe after years of operation at elevated temperature.

This is why ASME B31.1 places strong emphasis on:

- Temperature-dependent allowable stress

- Long-term material behavior

- Historical operating experience

Ignoring these aspects is one of the most common causes of premature piping failures in power plants.

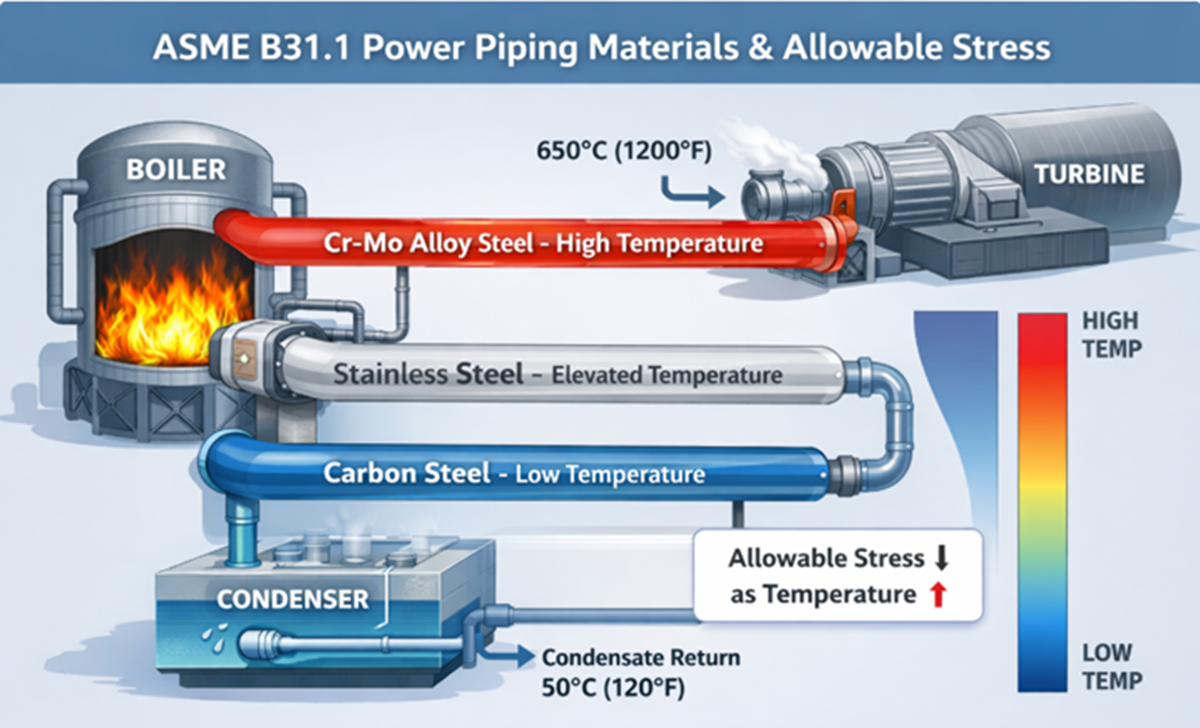

Common Materials Used in ASME B31.1 Power Piping

Carbon Steel

Carbon steel is widely used in ASME B31.1 systems, but only where temperature allows.

Typical Applications

- Condensate piping

- Low-temperature boiler feedwater

- Auxiliary utility lines

- Drain and vent systems

At moderate temperatures, carbon steel offers:

- Good weldability

- Low cost

- Proven service history

However, carbon steel loses strength rapidly as temperature increases. Above certain temperature limits, its allowable stress drops sharply, making it unsuitable for main steam or reheat services.

Key Limitation

Carbon steel is generally not suitable for sustained high-temperature steam service.

Low Alloy Steel (Chrome-Moly Steels)

Low alloy steels containing chromium and molybdenum are the workhorse materials of power piping.

Common grades include:

- P11 (1.25Cr–0.5Mo)

- P22 (2.25Cr–1Mo)

- P91 / P92 (9Cr–1Mo class)

Why Alloy Steels Are Used

Compared to carbon steel, alloy steels provide:

- Higher allowable stress at elevated temperature

- Better creep resistance

- Improved oxidation resistance

- Longer service life under thermal cycling

Practical Example – Main Steam

Main steam piping operating at temperatures above 500°C is almost always designed using chrome-moly alloy steel. Carbon steel would require impractically thick walls and would still suffer from long-term creep damage.

Stainless Steel

Stainless steel is used in ASME B31.1 where:

- Very high temperature capability is required

- Oxidation resistance is critical

- Corrosion resistance is needed

Typical Applications

- Superheater outlet piping

- Special utility services

- High-temperature bypass lines

Design Considerations

While stainless steel performs well at high temperature, it:

- Has higher thermal expansion than carbon and alloy steel

- Requires careful stress analysis

- Is more expensive and demanding in fabrication

Stainless steel is not a universal replacement for alloy steel and must be selected with care.

Material Specification vs Piping Class

A common beginner misunderstanding is confusing material specification with piping class.

Material Specification

Defines:

- Chemical composition

- Mechanical properties

- Heat treatment requirements

Examples: ASTM A106, ASTM A335, ASTM A312

Piping Class

Defines:

- Which material specification is allowed

- Pipe thickness or schedule

- Fittings, flanges, valves

- Bolting and gasket materials

In ASME B31.1 projects:

- Material selection is validated through allowable stress

- Final implementation happens through piping class

You never select material in isolation—you select it as part of a piping class.

Allowable Stress Concept in ASME B31.1

Allowable stress is the maximum stress permitted in a piping material under specified conditions to ensure safe operation.

In ASME B31.1:

- Allowable stress is temperature dependent

- Values decrease as temperature increases

- Long-term strength and creep are explicitly considered

Allowable stress values are provided in code tables and are based on:

- Yield strength

- Tensile strength

- Creep rupture data

- Service life expectations

This approach ensures that piping remains safe not just on day one, but after years of operation.

Effect of Temperature on Allowable Stress

Temperature has a profound impact on material strength.

As temperature increases:

- Yield strength decreases

- Tensile strength decreases

- Creep deformation accelerates

ASME B31.1 accounts for this by reducing allowable stress at higher temperatures.

Practical Impact

A pipe designed at the same pressure but higher temperature may require:

- Thicker wall

- Higher alloy material

- Different piping class

This is why temperature often governs power piping design more than pressure.

Creep and Long-Term Material Behavior

Creep is the slow, time-dependent deformation of material under constant stress at high temperature.

In power piping:

- Creep damage accumulates gradually

- Visible deformation may not appear until late stages

- Failure can be sudden and severe

ASME B31.1 allowable stress values are intentionally conservative to limit creep over the intended service life.

This is a key difference from oil and gas piping, where corrosion and fatigue are often more critical than creep.

Practical Material Selection Examples

Main Steam Line

- Very high temperature

- Long continuous operation

- Alloy steel (P22, P91 class)

- Strict allowable stress limits

Boiler Feedwater

- High pressure

- Moderate temperature

- Carbon steel or low alloy steel depending on temperature

- Corrosion and erosion also considered

Condensate System

- Low temperature

- Moderate pressure

- Carbon steel commonly used

- Material selection driven more by corrosion allowance than creep

These examples show that service conditions drive material choice, not habit or cost alone.

Typical Material Selection Mistakes

Some common errors seen in projects include:

- Selecting material based only on pressure

- Ignoring long-term temperature exposure

- Applying ASME B31.3 material logic to ASME B31.1 systems

- Assuming room-temperature strength applies at operating temperature

- Mixing materials without considering thermal expansion mismatch

These mistakes often surface late—during stress analysis, fabrication, or even operation.

Frequently Asked Questions (FAQ)

Q1: Why is alloy steel preferred over carbon steel in high-temperature power piping?

Because alloy steels retain strength at elevated temperature and resist long-term creep damage better than carbon steel.

Q2: Does allowable stress depend on operating temperature or design temperature?

Allowable stress is based on design temperature, which represents the maximum metal temperature expected.

Q3: Can stainless steel always replace alloy steel in power piping?

No. Stainless steel has different thermal and mechanical behavior and must be evaluated carefully for each application.

Conclusion: Materials Define the Life of Power Piping

In ASME B31.1 power piping, materials and allowable stress are not secondary details. They define how the piping system behaves over decades of operation.

Understanding how temperature, time, and stress interact allows piping engineers to:

- Select the right materials

- Avoid creep-related failures

- Design systems that operate safely for their intended life

Once material selection and allowable stress are understood, the next logical step is pipe thickness calculation, where these concepts are applied quantitatively.