In any process plant, pipes are more than just hollow tubes carrying fluid. They are pressure-containing components expected to work safely for 20, 25, sometimes 40 years. During that life, corrosion is not a possibility — it is a certainty.

That is where corrosion allowance comes in.

As a piping engineer, understanding corrosion allowance is one of the first real “plant-thinking” skills you must develop. It connects materials, process conditions, codes, and real operating experience.

Table of Contents

What Is Corrosion Allowance and Why It Is Important

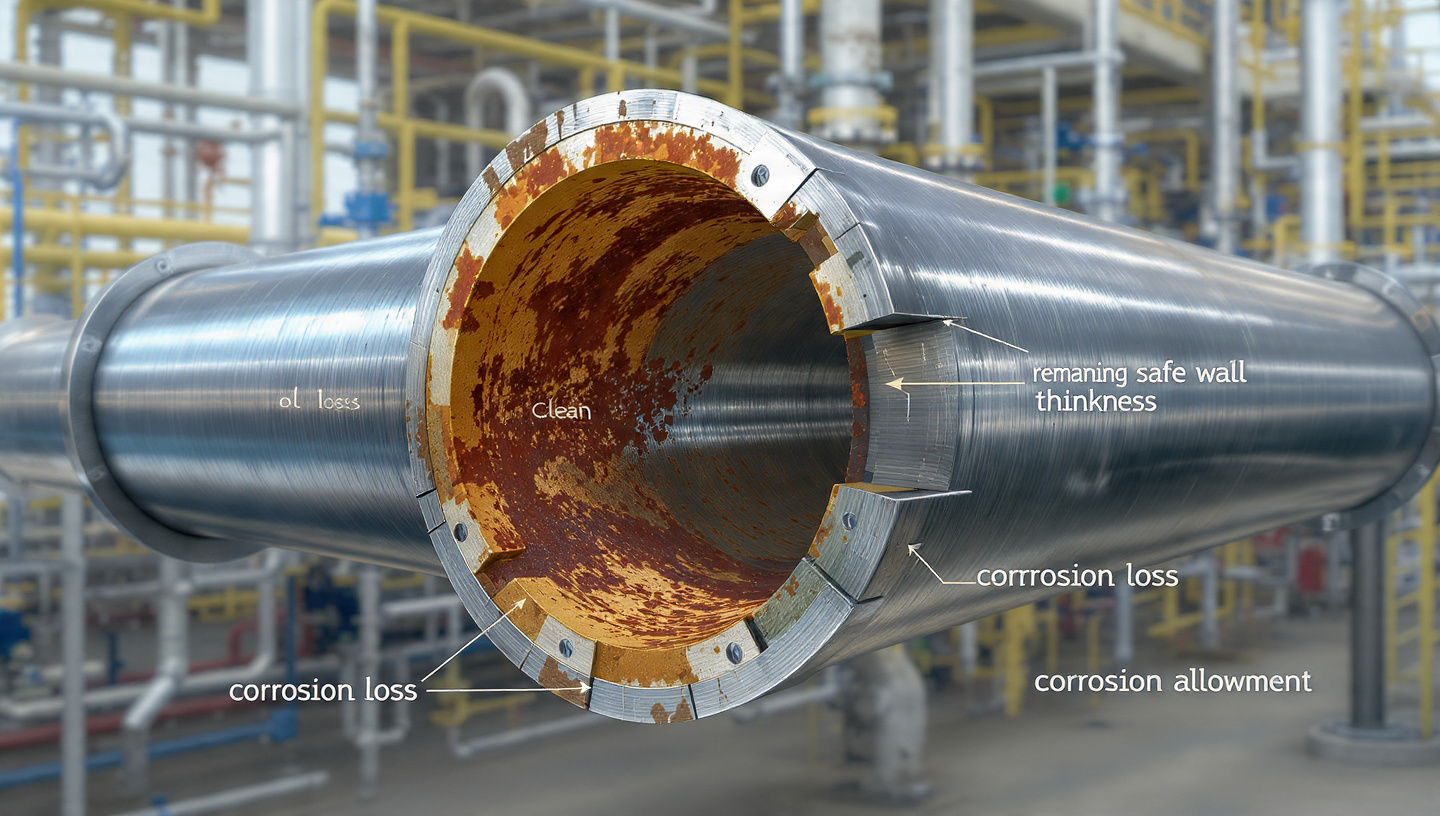

Corrosion allowance (CA) is the extra thickness added to the calculated minimum pipe wall thickness to compensate for material loss due to corrosion, erosion, or chemical attack over the design life of the piping system.

In simple terms:

We knowingly make the pipe thicker today because we expect it to become thinner tomorrow.

Without corrosion allowance:

- Pipes may meet pressure requirements on paper

- But fail prematurely in service

- Leading to leaks, shutdowns, or worse, safety incidents

Corrosion allowance is a design safety margin, but it is not random. It is based on:

- Fluid corrosiveness

- Operating temperature

- Past plant experience

- Industry practice

- Code requirements

If you are new to piping, first understand the basics of piping systems from What is Piping

Corrosion Allowance vs Pipe Thickness – Clear the Confusion

One common confusion among junior engineers is mixing up:

- Required thickness

- Nominal thickness

- Corrosion allowance

Let’s break it down simply.

- Calculated thickness

- Derived from pressure, temperature, diameter, and material

- As per ASME B31 code formulas

- Corrosion allowance

- Added on top of calculated thickness

- Nominal thickness (Schedule)

- Standard pipe thickness available in the market

So the logic is:

Required Thickness = Pressure Thickness + Corrosion Allowance

Then you select a pipe schedule that is equal to or greater than this required thickness.

If you are not comfortable with pipe sizes and schedules yet, revise NPS, DN & Schedule.

Why Corrosion Is Inevitable in Piping Systems

In textbooks, corrosion looks neat and predictable. In plants, it is messy and localized.

Common real-world corrosion mechanisms include:

- Uniform corrosion (general wall thinning)

- Pitting corrosion

- Crevice corrosion

- Erosion-corrosion

- MIC (Microbiologically Influenced Corrosion)

Even clean-looking services like:

- Condensate

- Cooling water

- Instrument air headers

can cause internal corrosion if oxygen, moisture, or bacteria are present.

That is why corrosion allowance is applied even when corrosion is not expected to be severe.

Typical Corrosion Allowance Values Used in Industry

There is no single universal value, but industry practice is well established.

Commonly Used Corrosion Allowance Values

| Service Type | Typical CA |

|---|---|

| Clean hydrocarbons | 1.5 mm |

| General process piping | 3 mm |

| Water services | 3 mm |

| Corrosive chemicals | 3–6 mm |

| Severe corrosion / slurry | 6 mm or more |

| Stainless steel (many services) | 0–1.5 mm |

Important: Zero corrosion allowance does NOT mean zero corrosion. It usually means corrosion is handled by material selection instead.

Corrosion Allowance and Piping Materials

Material selection and corrosion allowance go hand in hand.

Carbon Steel Piping

Carbon steel is the workhorse of piping engineering:

- Low cost

- Easy fabrication

- Good mechanical strength

But it corrodes easily in the presence of:

- Water

- Oxygen

- Acids

- CO₂ / H₂S

That is why carbon steel pipes almost always have 1.5 to 3 mm corrosion allowance.

In refineries and chemical plants, 3 mm CA is very common for carbon steel.

Low Temperature Carbon Steel (LTCS)

LTCS is selected mainly for low-temperature toughness, not corrosion resistance.

Corrosion behavior is similar to carbon steel, so:

- Corrosion allowance values are usually the same as CS

- Do not reduce CA just because the material is LTCS

Alloy Steel Piping

Alloy steels (like Cr-Mo) are selected for:

- High temperature strength

- Creep resistance

They are not selected primarily for corrosion resistance.

In services like:

- Hot hydrogen

- High-temperature hydrocarbons

Alloy steel pipes still use corrosion allowance, commonly 1.5–3 mm, unless process data confirms otherwise.

Stainless Steel Piping

Stainless steel resists corrosion through a passive chromium oxide layer.

In many clean services:

- Corrosion allowance may be 0 mm

- Or a nominal 1.5 mm for conservatism

However, stainless steel is not immune:

- Chlorides cause pitting

- High temperature can break passivation

- Dead legs can corrode

Experienced engineers are careful with “zero CA” decisions.

FAQ. on Corrosion Allowance

1: Can corrosion allowance be zero in piping design?

Yes, corrosion allowance can be zero, but only in specific and well-justified cases.

Zero corrosion allowance is typically used when:

- The material itself provides corrosion resistance (e.g., stainless steel, titanium, certain alloys)

- The fluid is non-corrosive and well controlled

- There is strong operating experience or corrosion study backing the decision

However, in real plants, zero CA should never be assumed casually.

Even stainless steel can suffer from:

- Chloride pitting

- Crevice corrosion

- Corrosion under insulation (CUI)

That is why many experienced engineers still keep 1.0–1.5 mm CA as a conservative margin, even for stainless steel, unless the service is very clean and proven.

2: Is corrosion allowance applied to fittings, flanges, and valves?

Yes — corrosion allowance applies to all pressure-containing components, not just straight pipes.

This includes:

- Elbows, tees, reducers

- Flanges

- Valve bodies

However, in practice:

- Pipes are selected by schedule (which includes CA implicitly)

- Fittings and flanges are selected by pressure class or standard, which already accounts for minimum thickness and corrosion allowance in their design codes (like ASME B16)

So while you don’t manually add CA to fittings during selection, the design philosophy still assumes corrosion allowance exists.

Understanding standard piping components is important here:

<u>Piping Components</u> (Link to: Piping Basics – Piping Components)

3: Who decides the corrosion allowance – process or piping?

Corrosion allowance is a shared responsibility, but the final implementation sits with piping.

Typically:

- Process engineering defines the fluid nature, corrosiveness, contaminants, and expected corrosion rate

- Materials or corrosion engineers may recommend CA based on studies or past data

- Piping engineering applies the corrosion allowance correctly in thickness calculation and material specification

A good piping engineer never blindly copies corrosion allowance from old projects.

They:

- Review process data

- Check service class

- Consider operating experience

- Apply engineering judgment

That balance between data and experience is what separates a designer from an engineer.

Non-Metallic Piping Materials

Materials like:

- HDPE

- FRP / GRP

- PVC / CPVC

do not use corrosion allowance in the traditional sense.