If you are new to piping engineering, or even if you are working in the field for a few years, you will often hear terms like NPS, DN, and Schedule. Many beginners get confused and sometimes even experienced engineers mix these terms during discussions.

I will explain NPS, DN, and Pipe Schedule in a very simple and practical way, exactly how it is used in real engineering projects, P&IDs, isometrics, and site construction.

Before going further, if you have not read the earlier basics, I strongly recommend reading

What is Piping and Piping vs Pipeline to understand the foundation.

Table of Contents

Why Pipe Size Terminology Is Important

In piping engineering, pipe size is not just a number. It directly affects:

- Flow capacity

- Pressure rating

- Pipe weight

- Stress calculation

- Support spacing

- Cost of piping material

Wrong understanding of pipe size can lead to wrong design, procurement issues, and site rework.

That is why every piping engineer must clearly understand NPS, DN, and Schedule.

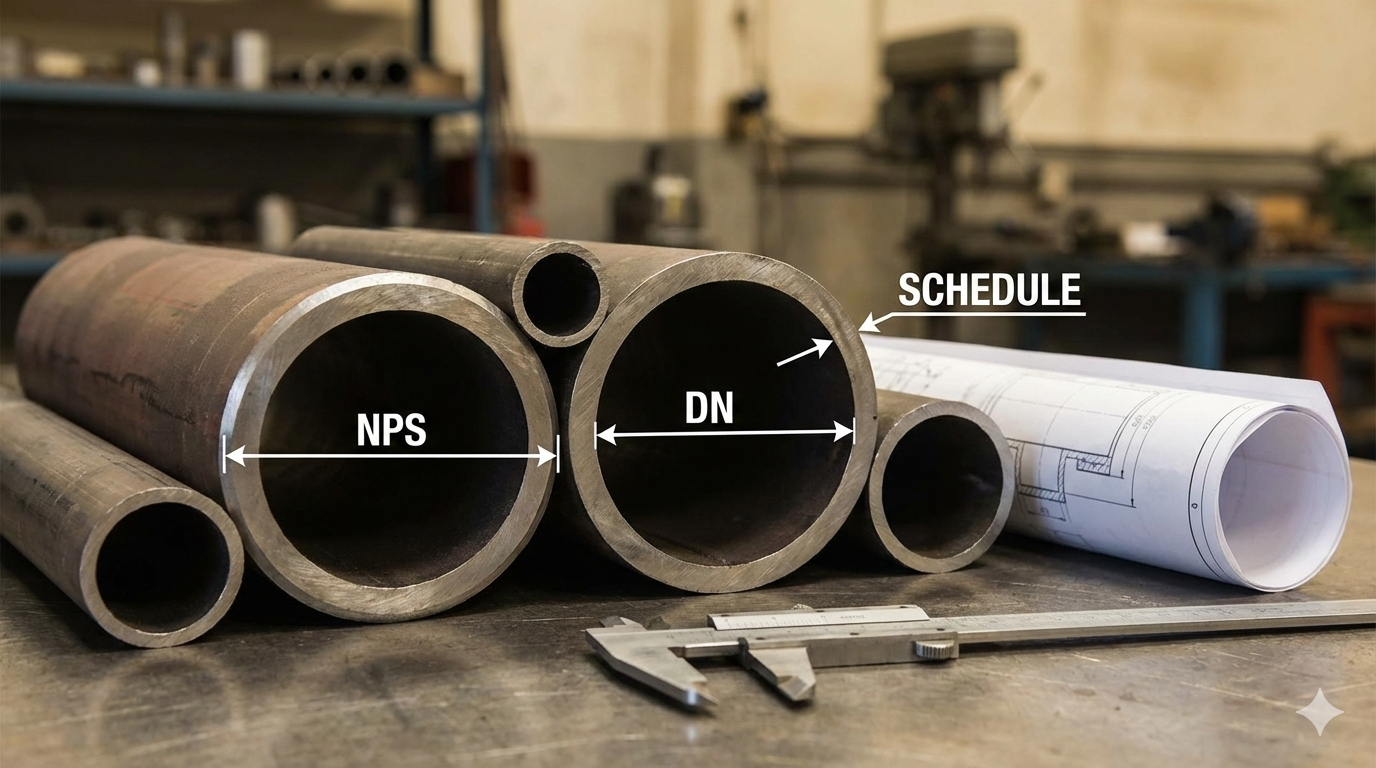

What Is NPS (Nominal Pipe Size)?

NPS stands for Nominal Pipe Size.

- It is a North American standard

- Defined as a dimensionless number

- Used to identify pipe size, not actual diameter

For pipes NPS 1/8″ to NPS 12″, the NPS number does NOT match the actual outside diameter.

For pipes NPS 14″ and above, the NPS number is equal to the outside diameter in inches.

Example:

- NPS 6 pipe → Outside Diameter = 6.625 inches

- NPS 12 pipe → Outside Diameter = 12.75 inches

- NPS 16 pipe → Outside Diameter = 16 inches

This confusion is very common among beginners.

👉 Important Rule:

NPS defines the pipe size, not the wall thickness.

Wall thickness is defined by Schedule, which we will discuss later.

Where NPS Is Used in Piping Engineering

You will see NPS mentioned in:

- P&ID line sizes

- Piping isometric drawings

- Material Take-Off (MTO)

- Purchase orders

- ASME B31 codes

- Pipe stress analysis

Example from drawing:

6″-P-150-CS

Here 6″ is the NPS.

What Is DN (Diameter Nominal)?

DN stands for Diameter Nominal.

- It is a metric designation

- Used mainly in Europe, Asia, and international projects

- Defined in ISO and EN standards

DN is also a dimensionless number, just like NPS.

Relation Between NPS and DN

| NPS (inch) | OD (inch) | DN (mm) | OD (mm) |

|---|---|---|---|

| 1/4″ | 0.540 | DN 8 | 13.72 |

| 3/8″ | 0.675 | DN 10 | 17.15 |

| 1/2″ | 0.840 | DN 15 | 21.34 |

| 3/4″ | 1.050 | DN 20 | 26.67 |

| 1″ | 1.315 | DN 25 | 33.40 |

| 1¼” | 1.660 | DN 32 | 42.16 |

| 1½” | 1.900 | DN 40 | 48.26 |

| 2″ | 2.375 | DN 50 | 60.33 |

| 2½” | 2.875 | DN 65 | 73.03 |

| 3″ | 3.500 | DN 80 | 88.90 |

| 3½” | 4.000 | DN 90 | 101.60 |

| 4″ | 4.500 | DN 100 | 114.30 |

| 5″ | 5.563 | DN 125 | 141.30 |

| 6″ | 6.625 | DN 150 | 168.28 |

| 8″ | 8.625 | DN 200 | 219.08 |

| 10″ | 10.750 | DN 250 | 273.05 |

| 12″ | 12.750 | DN 300 | 323.85 |

| 14″ | 14.000 | DN 350 | 355.60 |

| 16″ | 16.000 | DN 400 | 406.40 |

| 18″ | 18.000 | DN 450 | 457.20 |

| 20″ | 20.000 | DN 500 | 508.00 |

| 22″ | 22.000 | DN 550 | 558.80 |

| 24″ | 24.000 | DN 600 | 609.60 |

👉 DN is approximately equal to the pipe inside diameter in millimeters, but not exact.

NPS vs DN – Are They Interchangeable?

No, they are not interchangeable numbers, but they represent the same pipe size system in different units.

For example:

- NPS 6 = DN 150

- Both represent the same physical pipe size

In international projects, you may see drawings mentioning:

DN150 (6″)

This avoids confusion between vendors and construction teams.

What Is Pipe Schedule?

Pipe Schedule defines the wall thickness of the pipe.

While NPS/DN defines pipe diameter, Schedule defines how thick the pipe wall is.

Common pipe schedules are:

- Schedule 10

- Schedule 20

- Schedule 40

- Schedule 80

- Schedule 160

- STD (Standard)

- XS (Extra Strong)

- XXS (Double Extra Strong)

How Schedule Affects Pipe Thickness

For the same NPS, different schedules have different thickness.

Example: NPS 6 Pipe

| Schedule | Wall Thickness (approx.) |

|---|---|

| Sch 10 | Thin wall |

| Sch 40 | Medium wall |

| Sch 80 | Thick wall |

👉 Outside diameter remains the same, only inside diameter changes.

This is a very important concept in piping design.

Why Different Pipe Schedules Are Used

Pipe schedule selection depends on:

- Design pressure

- Design temperature

- Corrosion allowance

- Fluid type

- Code requirement (ASME B31.3, B31.1, etc.)

For example:

- Utility lines → Sch 10 or Sch 20

- Process lines → Sch 40

- High-pressure lines → Sch 80 or higher

Pipe thickness calculation is explained in detail in

Pipe Thickness Calculation.

Common Mistakes Engineers Make

After 25 years in piping design and site execution, I have seen common mistakes:

- Assuming NPS equals actual diameter

- Mixing DN and mm actual size

- Forgetting to mention schedule in drawings

- Using wrong schedule during procurement

- Not matching pipe schedule with fittings and flanges

👉 Always remember:

Pipe, fittings, and flanges must have matching pressure rating and schedule compatibility.

This topic connects directly with

Flanges & Fittings .

Practical Tip from Site Experience

On site, workers often say:

“6 inch pipe”

They mean NPS 6, not 6-inch OD or ID.

As an engineer, always specify full description:

NPS 6, Sch 40, ASTM A106 Gr.B

Clear communication avoids costly mistakes.

FAQ

Q1. What is the full form of NPS in piping?

NPS stands for Nominal Pipe Size. It is a standard way to define pipe size in inches and is mainly used in ASME and ANSI piping systems. NPS is a nominal value and does not represent the exact inside or outside diameter of the pipe.

Q2. What is the difference between NPS and DN?

The main difference is:

- NPS is based on inch system

- DN is based on metric system

However, both represent the same physical pipe size.

Example:

NPS 6 = DN 150

Q3. Does pipe schedule change the outside diameter?

No.

For a given NPS:

- Outside diameter remains constant

- Inside diameter changes based on schedule

This is a very important concept in piping design and stress analysis.

Final Words

Understanding NPS, DN, and Schedule is a core skill for every piping engineer, designer, and site supervisor. Once you master this topic, reading drawings, preparing MTOs, and handling site queries becomes much easier.

In the next piping basics article, we will discuss Pipe Materials, which is another critical foundation topic.

👉 Continue learning with

Pipe Materials in Piping Engineering

5 thoughts on “NPS, DN, and Schedule – Complete Guide for Piping Engineers”