ASME B31.1 Thermal Expansion & Stress Analysis Explained – Power Piping Design Guide

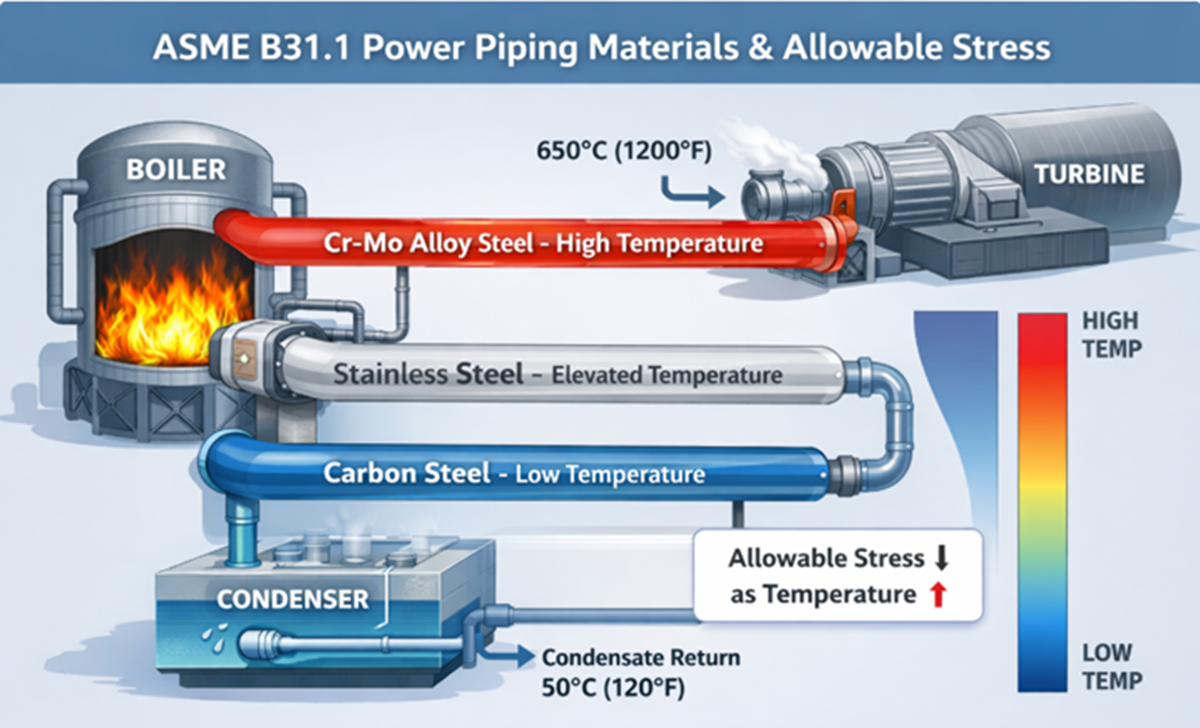

Learn how thermal expansion, stress analysis, and pipe supports are handled in ASME B31.1 power piping. Practical examples, plant failures, and beginner-friendly explanations by an experienced piping engineer. Introduction Why Thermal Expansion Matters in Power Piping In power plant piping systems, temperature is the real enemy—not pressure. Many junior engineers focus heavily on design pressure, … Read more