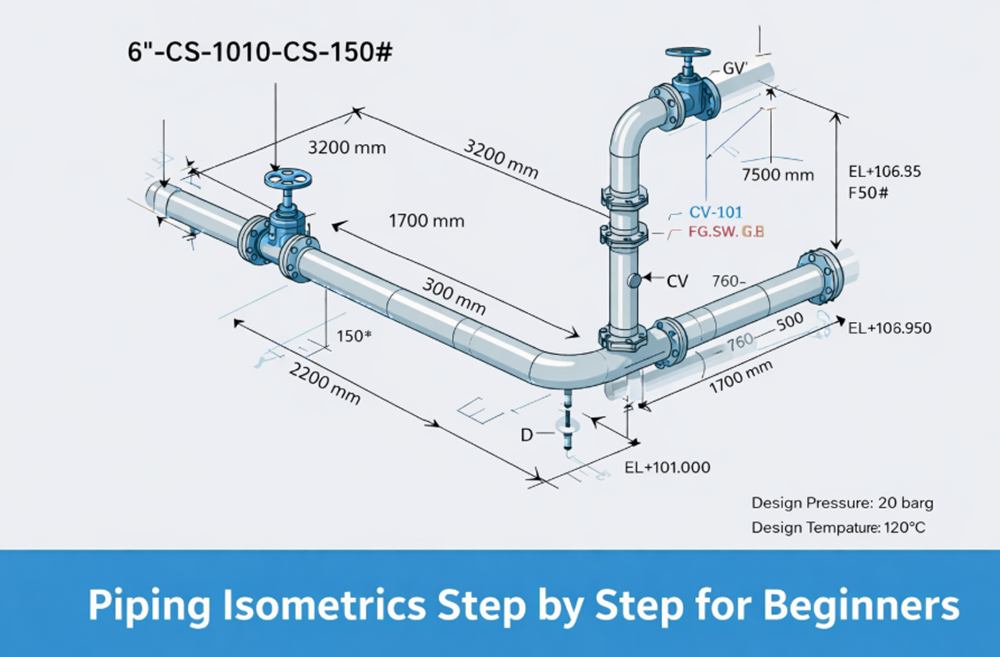

Piping Isometrics Step-by-Step Guide for Beginners | ASME B31.1

Learn piping isometrics step by step with clear explanations designed for beginners in piping engineering. This practical guide explains piping design using real plant examples, including P&ID interpretation, line numbering system, piping class, and material specification. Based on ASME B31.1 power piping and industry best practices used in oil and gas piping projects. Ideal for … Read more